Polluted Air Harmful To Health

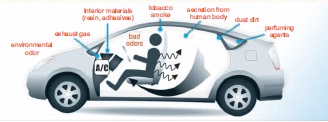

Due to the significant increase of global traffic and the inevitable worsening of pollution levels, we are exposed to many pollutants which enter the interior of the vehicles through the air conditioning and heating systems. The polluted air contains large quantities of dust, pollen, soot and other particles, as well as gases which are harmful to health. A high concentration of pollutants in the air can lead to fatigue, headaches, nausea and allergic reactions. Filters that have not been replaced in time can also cause poor visibility inside the car due to misted-up windows increasing the risk of accidents.

Cabin filters have been developed in the last decade and nowadays most cars are fitted with them. The main purpose is to clean the polluted air that enters into the interior of the car thus ensuring a better atmosphere inside the car.

Comprehensive Cabin Filter Range

To address the needs of consumers with respect to pollution, ALCO has developed a wide range of more than 300 filters applicable for cars, vans and trucks.

The range of cabin filters is continuously extended with additions of new part numbers applicable for new cars that enter into the market.

A cabin filter catalogue is issued annually with the following information:

-

Applications and cross-references

-

Dimensions and filter photo

General location diagrams for assisting the person that replaces the filter.

Instalation Locations:

Due to the increased difficulty identifying the exact location of installation ALCO has created a schematic image locator to specify the exact location of each cabin filter.

By searching the specific cabin filter in the online catalogue and clicking on the LOCATION link below the filter image it can be specified the exact location for replacing the cabin filter.

High Spec Filter Media

High Spec Filter Media

ALCO uses multilayered synthetic media, able to repel moisture and to trap harmful particles down to 0.3micron.

For additional filtering requirements cabin air filters with activated carbon keep harmful exhaust fumes, dirt and dust as well as high ozone concentrations and unpleasant smells outside the car cabin.

ALCO cabin filters use non-woven materials that are natural and free of chemical impregnation and odours Currently there are two types of cabin filters:

-

Pollen Filters: To effectively protect against dust, pollen, soot and other dirt particles

-

Active Carbon Filters: For added protection against unpleasant odours, smells and harmful gases.

Advanced Manufacturing Technology

Advanced filter technology and the latest development in production machinery are used for the manufacturing of cabin filters.

The filter media is firstly unwound from its roll and fed through a material buffer which ensures an uninterrupted operation also when changing the material roll. In the next step, the material is pleated by a High Speed blade Pleater and gets a thermal conditioning which takes out the mechanical tensions from the material and prepares the pleat for the next production steps.

Following, the pleats enter the pitching unit which has been preset to the desired filter width and pleat pitch.

Then, the pleats are locked into position as long as their longitudinal sides have been glued with side stripes. For this purpose, the production line features two unwinders for the side stripes, a hot-melt unit for applying hot-melt to the stripes as well as an edge pressing mechanism for gently pressing the stripes onto the sides of the locked pleats.

Afterwards, the glued sides are cooled down while forwarding the filter pack into an automatic cross cutter for cutting the pack into elements of desired length. Finally, the filter elements are forwarded by a conveyor belt for printing and packaging.

All mentioned production steps take place without intervention of an operator.